Packaging Machines

Packaging machines play a crucial role in the modern manufacturing industry by automating the process of packaging products efficiently. These machines are designed to handle a variety of packaging materials and formats, ensuring that products are securely and accurately packed before they are shipped to consumers. In this explanation, we will delve into the types of packaging machines, their working principles, safety considerations, and guidelines to ensure proper usage.

Types of Packaging Machines:

- Filling Machines: These machines are used to fill containers with liquid, powder, or granular products. Examples include liquid filling machines, powder filling machines, and auger fillers.

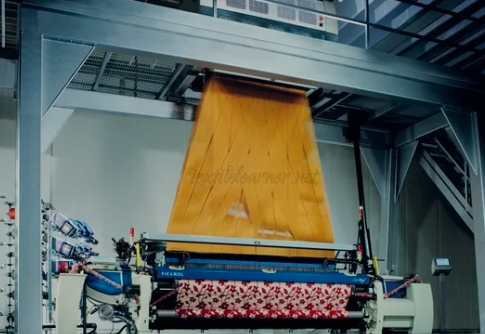

- Wrapping Machines: Wrapping machines are designed to wrap products with a protective material, such as shrink wrap or stretch film. Examples include stretch wrapping machines and shrink wrapping machines.

- Sealing Machines: Sealing machines are used to seal products in various types of packaging, such as bags, pouches, or containers. Examples include heat sealers and induction sealers.

- Labeling Machines: Labeling machines apply labels to products, ensuring accurate and consistent labeling. They are widely used in industries such as food and beverage, pharmaceuticals, and cosmetics.

- Cartoning Machines: Cartoning machines automate the process of placing products into cartons or boxes. They are commonly used in the packaging of pharmaceuticals, food products, and consumer goods.

- Coding and Marking Machines: These machines are used to print information such as expiry dates, batch numbers, and barcodes directly onto packaging materials.

Working Principles of Packaging Machines: Packaging machines operate based on the principles of automation, precision, and speed. The specific working principle depends on the type of machine, but common elements include product feeding, material handling, and sealing or wrapping processes. Sensors and control systems ensure accuracy and consistency in the packaging process, minimizing errors and reducing waste.

Safety Considerations:

- Training and Certification: Only trained and certified operators should operate packaging machines. Proper training ensures that operators understand the machine’s operation, safety features, and emergency procedures.

- Protective Equipment: Operators should wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection, to safeguard against potential hazards.

- Machine Guarding: Packaging machines should be equipped with guards and safety interlocks to prevent access to moving parts during operation. These guards protect operators from injuries and ensure safe operation.

- Emergency Stop Procedures: Machines must have clearly marked emergency stop buttons that instantly halt all machine functions in case of an emergency. Operators should be trained on how to use these stops effectively.

- Regular Maintenance: Regular maintenance of packaging machines is crucial to ensure optimal performance and prevent malfunctions that could pose safety risks. Maintenance tasks should be performed by qualified personnel.

Guidelines for Safe Usage:

- Read the Manual: Operators should thoroughly read and understand the machine’s operating manual. It provides essential information on proper usage, maintenance procedures, and safety precautions.

- Inspect Before Operation: Before starting the machine, operators should conduct a visual inspection to ensure that all components are in good condition. Any damaged or worn parts should be replaced immediately.

- Follow Operating Procedures: Operators should strictly adhere to the manufacturer’s operating procedures. Deviating from these procedures can result in malfunctions and pose safety risks.

- Monitor Machine Performance: Operators should continuously monitor the machine’s performance during operation. Unusual noises, vibrations, or other abnormalities should be investigated promptly.

- Keep the Workspace Clean: A clean and organized workspace reduces the risk of accidents and ensures that the machine operates efficiently. Remove any debris or obstructions from the machine area.

- Handle Materials Safely: When loading materials into the machine, operators should follow proper lifting techniques to prevent strains or injuries. They should also be aware of the characteristics of the materials being used.

In conclusion, packaging machines are invaluable in modern manufacturing, enhancing efficiency and ensuring product quality. However, their safe operation requires careful attention to guidelines, proper training, and regular maintenance. Adhering to safety measures protects both operators and the integrity of the packaged products.