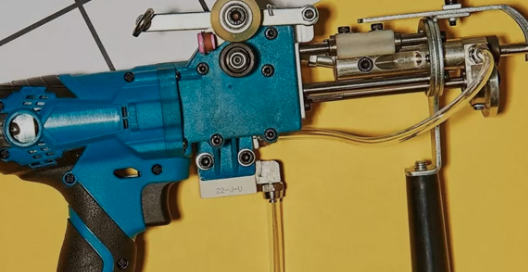

Importance Of High Quality Tufting Machines:

In the dynamic realm of textile manufacturing, the significance of high-quality tufting machines cannot be overstated. These sophisticated pieces of engineering prowess play a pivotal role in the production of various textile products, from carpets and rugs to upholstery and beyond. In this comprehensive exploration, we delve into the multifaceted importance of these cutting-edge tufting machines, shedding light on their impact on product quality, efficiency, and the overall landscape of the textile industry.

Understanding Tufting Machines: A Technological Marvel

Before we embark on the journey to unravel the importance of high-quality tufting machines, let’s gain a deeper understanding of their intricate mechanics. Tufting machines are specialized devices used in the textile industry to create tufted textiles by punching yarn through a primary backing fabric. These machines have undergone significant advancements over the years, evolving into highly sophisticated systems that contribute to the efficiency and precision of textile production.

Unparalleled Precision: Enhancing Product Quality

High-quality tufting machines are characterized by their precision and accuracy, which directly translate into superior product quality. The ability to precisely control the insertion of yarn into the backing material ensures uniformity in the pile height, density, and pattern of the finished textile product. This precision is paramount, particularly in industries where aesthetics and consistency are key, such as carpet manufacturing.

Bold Innovation with HTL1 Technology

One of the revolutionary advancements in tufting machine technology is the incorporation of High-Tech Level 1 (HTL1) capabilities. This bold innovation brings a new dimension to precision and efficiency. HTL1 technology utilizes advanced sensors, intelligent algorithms, and real-time data analytics to optimize the tufting process. This not only enhances the quality of the final product but also allows for adaptability and customization, meeting the diverse needs of the market.

Accelerating Production Efficiency: A Competitive Edge

In the fast-paced landscape of textile manufacturing, efficiency is a cornerstone for success. High-quality tufting machines are designed to operate seamlessly, minimizing downtime and maximizing output. The incorporation of innovative features, such as automated yarn tension control and rapid changeover mechanisms, ensures that production processes are streamlined for optimal efficiency.

Reducing Lead Times: Meeting Market Demands

With the global demand for textiles constantly on the rise, manufacturers face the challenge of meeting market demands without compromising on quality. High-quality tufting machines equipped with HTL1 technology excel in reducing lead times by offering swift changeovers between different production setups. This agility not only caters to the dynamic nature of market trends but also positions manufacturers to respond promptly to custom orders and unique design requirements.

HTL1 in Action: Real-Time Adaptive Production

HTL1 technology takes production efficiency to new heights by enabling real-time adaptive production. The system continuously monitors and adjusts parameters such as yarn tension, stitch density, and pattern alignment based on feedback from sensors. This level of adaptability ensures that the tufting machine optimizes its performance throughout the production run, delivering consistent and high-quality output.

Upholding Industry Standards: Quality Assurance and Compliance

In an industry where adherence to quality standards and regulatory compliance is non-negotiable, the role of high-quality tufting machines becomes even more critical. These machines are engineered to meet or exceed industry standards, ensuring that the final products not only meet customer expectations but also adhere to safety and quality regulations.

Quality Assurance Protocols: Ensuring Consistency

Manufacturers utilizing high-quality tufting machines can implement robust quality assurance protocols throughout the production process. The precision and reliability of these machines contribute to the consistency of the final product, reducing variations and defects. This consistency is vital, especially in industries where products must meet strict specifications for commercial and residential use.

HTL1: Elevating Quality Assurance Practices

HTL1 technology plays a pivotal role in quality assurance by providing real-time insights into the production process. By continuously monitoring variables and making instantaneous adjustments, HTL1 ensures that deviations from quality standards are identified and addressed promptly. This proactive approach minimizes the risk of defects, ultimately bolstering the reputation of manufacturers for delivering high-quality textiles.

Embracing Sustainability: A Green Revolution in Textile Manufacturing

In an era where environmental consciousness is paramount, high-quality tufting machines contribute to the sustainable evolution of textile manufacturing. The integration of energy-efficient components, waste reduction mechanisms, and eco-friendly materials in these machines aligns with the industry’s growing commitment to sustainable practices.

Energy Efficiency: Reducing Carbon Footprint

One of the notable features of high-quality tufting machines is their energy-efficient design. Through the use of advanced motors, intelligent power management systems, and optimized workflows, these machines minimize energy consumption without compromising on performance. This not only translates into cost savings for manufacturers but also contributes to the reduction of the industry’s overall carbon footprint.

HTL1 and Sustainable Manufacturing

HTL1 technology extends its influence to sustainability by providing insights into energy consumption patterns. By analyzing data on power usage during different stages of the tufting process, manufacturers can identify opportunities for further optimization. This data-driven approach, facilitated by HTL1, empowers manufacturers to make informed decisions that align with sustainable practices.

Conclusion: Tufting Machines Redefined for the Future

In conclusion, the importance of high-quality tufting machines, accentuated by bold innovations such as HTL1 technology, reverberates across the textile industry. These machines not only uphold the standards of precision and efficiency but also contribute to sustainable manufacturing practices. As the textile landscape continues to evolve, manufacturers armed with cutting-edge tufting machines are poised to lead the way, delivering products that seamlessly blend quality, efficiency, and environmental responsibility. The era of tufting machines redefined for the future has arrived, and it is marked by precision, efficiency, and a commitment to excellence.