Importance Of High Quality Laser Cutting Machines:

In the ever-evolving landscape of manufacturing and fabrication, the role of technology is pivotal. Among the numerous advancements, high-quality laser cutting machines stand out as transformative tools that have revolutionized the way materials are processed. This article delves into the importance of these cutting-edge machines, exploring their impact on industries, the advantages they offer, and the role they play in shaping the future of manufacturing.

Understanding Laser Cutting Technology

Laser cutting technology involves the use of a highly focused laser beam to cut through various materials with precision and accuracy. The process relies on the intense heat generated by the laser to vaporize or melt the material, leaving behind a clean and well-defined cut. The quality of laser cutting machines is a critical factor in determining the efficiency and effectiveness of this process.

Precision and Accuracy: Cornerstones of High-Quality Laser Cutting

One of the primary reasons high-quality laser cutting machines are indispensable is their unparalleled precision and accuracy. Whether working with metals, plastics, or other materials, these machines can achieve cuts with tolerances measured in fractions of a millimeter. This level of precision is crucial in industries where tight specifications and exacting standards are non-negotiable.

Versatility in Material Processing

The versatility of high-quality laser cutting machines extends beyond the precision of cuts. These machines can handle an extensive range of materials, from thin sheets to thicker plates, offering manufacturers flexibility in material selection. This adaptability makes laser cutting an attractive option for industries with diverse material requirements, such as aerospace, automotive, and electronics.

Increased Efficiency and Cost Savings

Investing in high-quality laser cutting machines translates to increased efficiency and substantial cost savings over time. The speed at which these machines operate, coupled with minimal material waste, contributes to enhanced productivity. Moreover, the precision of laser cutting reduces the need for secondary finishing processes, saving both time and resources.

Advancements in Automation and Integration

The integration of high-quality laser cutting machines with advanced automation systems marks another milestone in modern manufacturing. Automated laser cutting processes not only improve efficiency but also reduce the risk of errors associated with manual operation. This seamless integration is a testament to the continuous evolution of technology in meeting the demands of the industry.

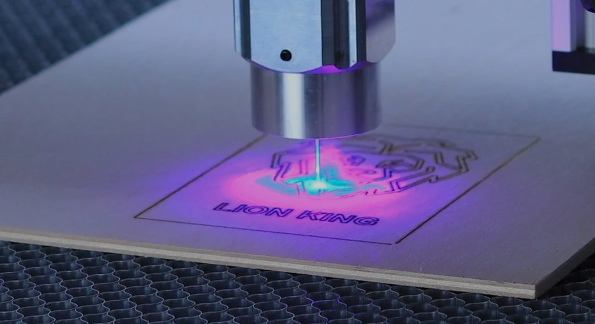

Achieving Intricate Designs and Patterns

Beyond the realm of basic cutting, high-quality laser cutting machines empower manufacturers to create intricate designs and patterns. This capability is particularly valuable in industries where aesthetics and unique detailing are paramount, such as in the production of decorative elements, signage, and customized components.

Environmental Sustainability

The emphasis on sustainable practices has become increasingly crucial in the manufacturing sector. High-quality laser cutting machines contribute to environmental sustainability by minimizing material waste and energy consumption. The precision of laser cutting results in less scrap, and the non-contact nature of the process reduces the need for consumables, making it an eco-friendly choice for forward-thinking industries.

Cutting-Edge Innovations in Laser Technology

The landscape of laser cutting continues to evolve with ongoing innovations in laser technology. From improvements in beam quality to the development of hybrid laser systems, manufacturers are continually exploring ways to push the boundaries of what is achievable with laser cutting machines. Staying abreast of these advancements is key for industries seeking to maintain a competitive edge.

Overcoming Challenges and Ensuring Reliability

While high-quality laser cutting machines offer numerous advantages, challenges such as maintenance requirements and initial investment costs must be considered. However, the long-term benefits, including increased productivity and reduced operational costs, often outweigh the initial challenges. Regular maintenance and adherence to best practices are crucial in ensuring the reliability and longevity of these advanced machines.

Conclusion

In conclusion, the importance of high-quality laser cutting machines in modern manufacturing cannot be overstated. Their precision, versatility, efficiency, and environmental sustainability make them indispensable tools for a wide range of industries. As technology continues to advance, so too will the capabilities of laser cutting machines, shaping the future of manufacturing and fabrication. Embracing these innovations is not just a choice; it is a strategic imperative for businesses aiming to thrive in the dynamic and competitive landscape of the 21st century.