Importance Of High Quality Knitting Machines:

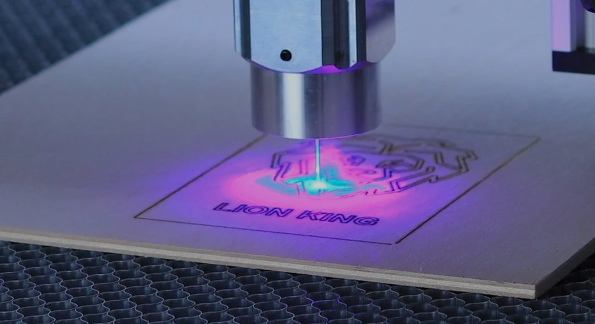

In the dynamic world of textile manufacturing, the role of knitting machines cannot be overstated. These technological marvels have undergone significant advancements, and the importance of high-quality knitting machines has become paramount. This article explores the transformative impact of state-of-the-art knitting machines on the textile industry, emphasizing their crucial role in achieving efficiency, precision, and innovation.

1. Enhanced Productivity and Efficiency

High-quality knitting machines are the backbone of a productive textile manufacturing process. They operate seamlessly, minimizing downtime and maximizing output. Modern machines come equipped with advanced features such as automated yarn control, efficient stitch formation, and rapid knitting speeds. This not only reduces labor costs but also ensures that production deadlines are met with precision and reliability.

2. Precision in Design and Fabrication

One of the key advantages of using high-quality knitting machines lies in their ability to produce intricate and precise designs. These machines offer a wide range of stitch patterns and textures, enabling manufacturers to meet the diverse demands of the market. Whether it’s creating complex patterns or ensuring uniform fabric density, the precision afforded by these machines contributes significantly to the overall quality of the end product.

3. Innovative Materials and Fabrics

The textile industry is witnessing a surge in demand for innovative materials and fabrics. High-quality knitting machines play a pivotal role in meeting this demand by facilitating the production of specialized fabrics such as smart textiles, technical textiles, and high-performance materials. The versatility of these machines enables manufacturers to experiment with different yarns and fibers, pushing the boundaries of what is possible in textile design.

4. Cost-Effective Sustainability

Sustainability is a growing concern in the textile industry, and high-quality knitting machines contribute to this aspect as well. These machines are designed with energy-efficient features, minimizing resource consumption and waste. Additionally, the precision in production reduces material wastage, making the entire manufacturing process more environmentally friendly. Investing in sustainable practices through high-quality knitting machines aligns with the global push towards eco-friendly manufacturing.

5. Customization and Small-Batch Production

Consumer preferences are becoming increasingly diverse, leading to a demand for customized and unique textile products. High-quality knitting machines empower manufacturers to engage in small-batch and on-demand production, catering to niche markets. This flexibility not only reduces excess inventory but also allows for quick adaptation to changing trends, giving businesses a competitive edge in the fast-paced world of fashion.

Conclusion

In conclusion, the importance of high-quality knitting machines in the textile industry cannot be overstated. These machines serve as catalysts for enhanced productivity, precision in design, innovation in materials, cost-effective sustainability, and customization. As technology continues to advance, investing in state-of-the-art knitting machines is not just a choice but a strategic necessity for textile manufacturers aiming to thrive in a competitive and ever-evolving market. The revolution brought about by these machines is not merely in the fabrics they produce but in reshaping the entire landscape of textile manufacturing.