Importance Of High Quality Digital Fabric Cutters:

In the dynamic realm of textile and garment manufacturing, the advent of technology has ushered in a new era of precision, efficiency, and innovation. High-quality digital fabric cutters have emerged as transformative tools, revolutionizing the traditional methods of cutting fabrics. This article delves into the significance of these cutting-edge devices and explores how they are reshaping the landscape of the textile industry.

The Evolution of Fabric Cutting Technology

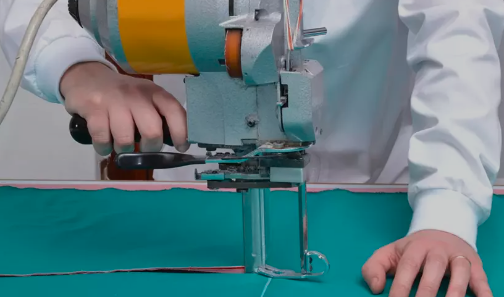

Bridging the Gap: Traditional vs. Digital

Historically, fabric cutting was a labor-intensive process, heavily reliant on manual skills and susceptible to errors. With the introduction of digital fabric cutters, the industry witnessed a paradigm shift. These cutting-edge machines leverage advanced technology to provide unparalleled accuracy, speed, and consistency in fabric cutting.

Precision Redefined: Laser and Computerized Cutting Systems

High-quality digital fabric cutters often employ laser and computerized cutting systems that redefine precision. The intricate patterns and designs that were once challenging to achieve with manual methods are now executed flawlessly with minimal margin for error. This not only enhances the overall quality of the final product but also significantly reduces material wastage.

Unlocking Operational Efficiency

Time is Money: Speed and Productivity

In the competitive landscape of textile manufacturing, efficiency is paramount. High-quality digital fabric cutters operate at remarkable speeds, allowing manufacturers to meet tight deadlines and respond swiftly to market demands. The integration of automation streamlines the cutting process, enabling a significant boost in overall productivity.

Consistency Across the Board

Consistency is a hallmark of quality, and digital fabric cutters deliver just that. The precision of these machines ensures that each cut is identical, eliminating variations that may arise with manual cutting. This consistency is crucial, particularly in industries where uniformity is a prerequisite, such as apparel manufacturing.

Cost-Efficiency and Sustainability

Reducing Material Wastage

Traditional cutting methods often result in substantial material wastage due to inaccuracies and inefficiencies. High-quality digital fabric cutters optimize material usage, minimizing waste and contributing to a more sustainable and cost-effective production process. This not only benefits manufacturers financially but also aligns with the growing emphasis on sustainable practices in the textile industry.

Scalability without Compromise

As businesses expand, scalability becomes a critical factor. Digital fabric cutters offer scalable solutions without compromising on efficiency or quality. This adaptability allows manufacturers to seamlessly integrate these cutting-edge machines into their growing operations, ensuring a smooth transition as production volumes increase.

The Technological Advancements in Digital Fabric Cutting

Smart Integration: IoT and Connectivity

Modern digital fabric cutters are not isolated machines; they are part of a connected ecosystem. Internet of Things (IoT) integration allows for real-time monitoring and control, optimizing the performance of these machines. Connectivity features enable seamless communication with other components of the production process, fostering a more intelligent and responsive manufacturing environment.

Enhanced Design Capabilities

Digital fabric cutters are not merely tools for precision cutting; they also empower designers with enhanced capabilities. These machines can interpret intricate design files and execute complex patterns with finesse. The marriage of technology and design opens up new creative possibilities, pushing the boundaries of what can be achieved in the realm of textile aesthetics.

Overcoming Challenges and Embracing the Future

Skill Transition and Training

The adoption of high-quality digital fabric cutters necessitates a shift in the skill set of the workforce. Manufacturers need to invest in training programs to ensure that their teams can effectively operate and maintain these advanced machines. While this presents a short-term challenge, the long-term benefits in terms of increased efficiency and reduced errors far outweigh the initial learning curve.

Embracing Industry 4.0

Digital fabric cutters are integral components of the broader Industry 4.0 revolution. Embracing the principles of automation, data exchange, and smart technologies, these machines represent a fundamental shift in how the textile industry operates. The integration of digital fabric cutters is not just an upgrade; it’s a strategic move towards a more interconnected and intelligent manufacturing ecosystem.

Conclusion: A Cutting-Edge Future

In conclusion, the importance of high-quality digital fabric cutters in the textile industry cannot be overstated. These machines go beyond mere tools for cutting; they are catalysts for efficiency, precision, and sustainability. As the industry continues to evolve, embracing the capabilities of digital fabric cutters is not just a choice but a necessity for those aiming to stay competitive and relevant in the dynamic landscape of modern textile manufacturing. The revolution has been unveiled, and the future is undoubtedly cutting-edge.