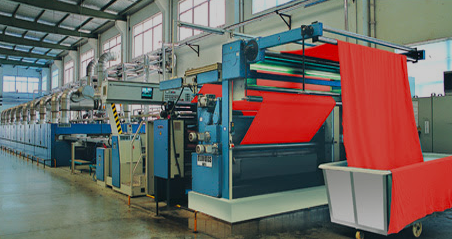

Importance Of High Quality Finishing Machines:

In the intricate world of manufacturing, the significance of high-quality finishing machines cannot be overstated. The finishing process is the final touchpoint in production, influencing the aesthetic appeal, functionality, and overall quality of the end product. Embracing advanced finishing technologies not only enhances the visual appearance but also contributes to the durability and performance of manufactured goods. This article delves into the pivotal role that high-quality finishing machines play in elevating standards across various industries.

Unveiling the Impact of Finishing in Manufacturing

1. Visual Appeal and Brand Image

The surface finish of a product is the first thing consumers notice. Whether it’s the sleek shine of a consumer electronics device or the flawless surface of a luxury automobile, the visual appeal contributes significantly to the perceived value and brand image. High-quality finishing machines ensure that the surface finish meets or exceeds customer expectations, leaving a lasting positive impression.

2. Precision and Consistency

In precision industries such as aerospace and medical manufacturing, the importance of precise finishing cannot be overstated. Finishing machines equipped with advanced technologies enable manufacturers to achieve unparalleled precision and consistency in surface finishes. This is crucial for components where even the slightest deviation can have severe consequences.

3. Corrosion Resistance and Longevity

Finishing is not just about aesthetics; it’s also a line of defense against environmental factors. High-quality finishing machines provide protective coatings that enhance corrosion resistance, ensuring the longevity of products. This is particularly vital in industries where exposure to harsh conditions is common, such as marine engineering or outdoor infrastructure.

4. Functional Performance Improvement

Finishing goes beyond appearances; it contributes to the functional performance of products. For instance, in the automotive sector, the surface finish of engine components can impact friction and wear characteristics, directly influencing fuel efficiency and engine lifespan. High-quality finishing machines facilitate the fine-tuning of surface properties for optimal functionality.

The Role of Advanced Technologies in Finishing

1. Automation and Efficiency

Modern finishing machines leverage automation and robotics to enhance efficiency and precision. Automated processes not only reduce production time but also minimize human errors, leading to a more consistent and high-quality finish. Manufacturers adopting these technologies gain a competitive edge by streamlining their production processes.

2. Innovations in Materials and Coatings

Continuous advancements in materials and coatings have revolutionized the finishing industry. High-quality finishing machines are equipped to handle a variety of materials and apply cutting-edge coatings that provide enhanced performance characteristics. From nanotechnology-inspired coatings to environmentally friendly finishes, these innovations contribute to sustainability and product excellence.

3. Customization and Flexibility

Consumer preferences are ever-evolving, and manufacturers need to adapt quickly to stay ahead. High-quality finishing machines offer customization and flexibility in the finishing process, allowing manufacturers to meet diverse consumer demands. Whether it’s matte or glossy finishes, texture variations, or unique patterns, these machines enable the production of customized products at scale.

Challenges and Considerations in Finishing

1. Environmental Sustainability

While achieving high-quality finishes, manufacturers must also address environmental concerns. The use of eco-friendly finishing processes and materials is becoming increasingly important. Balancing product excellence with sustainability is a challenge that requires constant innovation in the field of finishing.

2. Cost Considerations

Investing in high-quality finishing machines involves upfront costs. However, manufacturers must weigh these costs against the long-term benefits, including improved product quality, reduced rework, and enhanced customer satisfaction. Understanding the return on investment is crucial for decision-makers in the manufacturing sector.

Conclusion

In conclusion, the importance of high-quality finishing machines extends far beyond the surface. From enhancing visual appeal and brand image to contributing to functional performance and longevity, the finishing process is a critical element in manufacturing. Embracing advanced technologies and addressing challenges such as environmental sustainability and cost considerations are essential for manufacturers looking to set new standards and thrive in an ever-evolving market. As industries continue to push boundaries, the role of high-quality finishing machines will remain central to delivering products that not only meet but exceed customer expectations.