Comprehensive Tips For Maintaining Commercial Laundry Equipment:

Commercial laundry equipment plays a crucial role in various industries, ensuring the efficient cleaning and maintenance of textiles. To maximize the lifespan and performance of these machines, it is essential to implement a proactive and comprehensive maintenance strategy. In this guide, we will delve into a detailed exploration of tips for maintaining commercial laundry equipment, covering everything from routine inspections to advanced troubleshooting techniques.

I. Regular Inspection and Cleaning

A. Daily Visual Inspections

Performing daily visual inspections is the first line of defense against potential issues. Train your staff to look for any signs of wear and tear, loose components, or unusual noises during these inspections.

B. Cleaning Filters and Drains

Clogged filters and drains can hinder the efficiency of your commercial laundry equipment. Develop a regular schedule for cleaning filters and drains to prevent blockages that can lead to more severe problems.

C. Ventilation System Maintenance

Proper ventilation is crucial for the optimal performance of laundry equipment. Ensure that exhaust vents are free from lint buildup and that the entire ventilation system is inspected and cleaned periodically.

II. Calibration and Adjustment

A. Regular Calibration Checks

Calibrate your commercial laundry equipment regularly to ensure accurate operation. This is particularly important for temperature-sensitive processes, as even slight deviations can impact the quality of the laundry and the efficiency of the equipment.

B. Adjusting Load Sizes

Overloading or underloading the machines can lead to inefficiencies and increased wear and tear. Educate your staff on the importance of following recommended load sizes to optimize the equipment’s performance.

C. Belt and Motor Tension

Check and adjust belt and motor tension as needed. Loose or overly tight belts can cause unnecessary strain on the equipment, leading to premature failure.

III. Lubrication Practices

A. Scheduled Lubrication

Develop a lubrication schedule for all moving parts of the equipment. Regular lubrication minimizes friction, reduces heat buildup, and extends the lifespan of bearings and other critical components.

B. Choosing the Right Lubricants

Ensure that you use the correct lubricants recommended by the equipment manufacturer. Different parts may require specific types of lubrication, so it’s essential to follow guidelines to avoid damage.

IV. Staff Training and Education

A. Comprehensive Training Programs

Invest in training programs for your staff to ensure they are well-versed in the proper operation and maintenance of commercial laundry equipment. Knowledgeable staff can identify issues early on and perform basic troubleshooting.

B. Emergency Response Training

Equip your staff with the skills to handle emergency situations. Quick and informed responses to equipment malfunctions can prevent further damage and minimize downtime.

V. Professional Servicing and Inspections

A. Scheduled Professional Inspections

In addition to daily visual inspections, schedule regular professional inspections by certified technicians. Professional inspections can uncover issues that may not be apparent during routine checks.

B. Prompt Repairs

Address any identified issues promptly. Ignoring small problems can lead to more significant breakdowns, resulting in costly repairs and extended downtime.

VI. Technology Integration for Monitoring

A. Remote Monitoring Systems

Consider implementing remote monitoring systems that allow you to keep track of equipment performance in real-time. These systems can provide valuable data for preventive maintenance and troubleshooting.

B. Utilizing Data Analytics

Employ data analytics to identify patterns and trends in equipment performance. This proactive approach can help predict potential issues before they escalate, optimizing the overall maintenance strategy.

VII. Environment Considerations

A. Proper Installation

Ensure that commercial laundry equipment is installed correctly, following manufacturer guidelines. Proper installation can prevent unnecessary vibrations, misalignments, and other issues that may arise from poor setup.

B. Temperature and Humidity Control

Maintain a controlled environment for your laundry facility. Extreme temperatures and humidity can affect the performance and lifespan of commercial laundry equipment, so it’s essential to keep the conditions within the recommended ranges.

VIII. Upgrading and Retrofitting

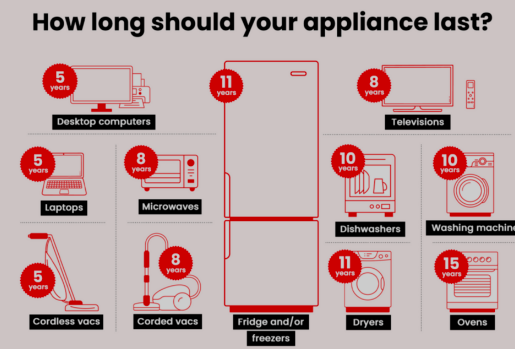

A. Regular Equipment Upgrades

Keep abreast of technological advancements in laundry equipment. Upgrading to newer models can improve efficiency, reduce energy consumption, and provide additional features that contribute to overall longevity.

B. Retrofitting for Efficiency

Consider retrofitting existing equipment with energy-efficient components or technologies. This not only extends the lifespan of the equipment but also aligns with sustainability goals.

IX. Documentation and Record-Keeping

A. Maintaining Maintenance Records

Keep detailed records of all maintenance activities. This documentation can provide valuable insights into the history of each piece of equipment, aiding in future troubleshooting and decision-making.

B. Utilizing Maintenance Software

Implement maintenance software to streamline record-keeping processes. These tools can automate scheduling, track maintenance history, and generate reports for a more organized and efficient maintenance approach.

Conclusion: Sustaining Excellence in Commercial Laundry Operations

In conclusion, the meticulous maintenance of commercial laundry equipment is paramount for ensuring its longevity and optimal performance. From daily visual inspections to embracing advanced technologies, a multifaceted approach is necessary to address the diverse challenges that may arise. By incorporating these tips into your maintenance strategy and fostering a culture of diligence and expertise among your staff, you can uphold the reliability and efficiency of your commercial laundry operations for years to come.